Maintaining consistent temperatures in commercial cooling and freezing equipment can often be a challenging and time-consuming task. Wave goodbye to these complications with our cutting-edge power and temperature management solution.

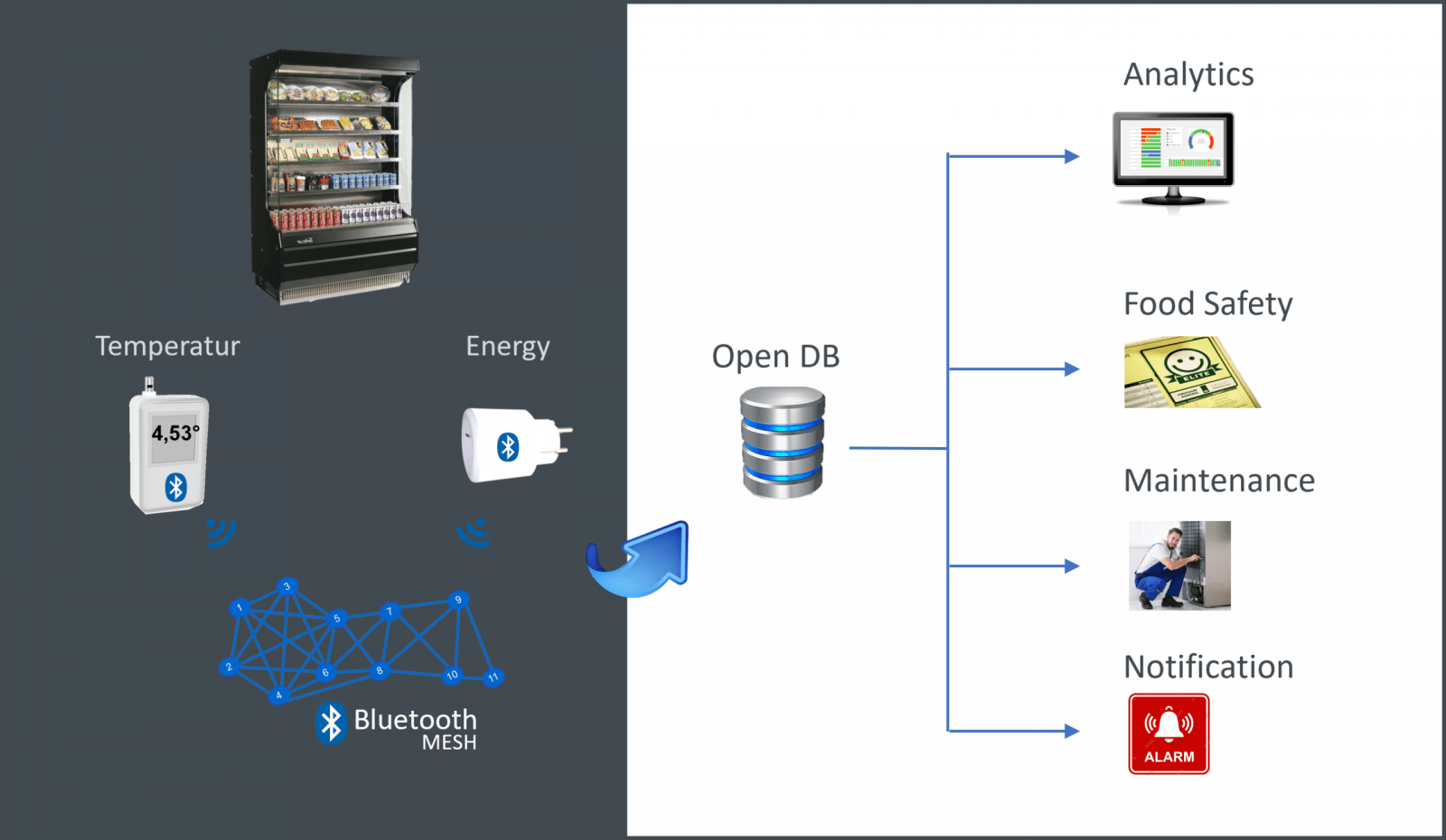

There is no need for costly upgrades. We handle the configuration of smart plugs and temperature sensors using our advanced AI algorithms. You can choose among smart meters that can handle from 12-120 amps.

Through power and temperature management, our system sends instant notifications to your staff regarding any temperature or power fluctuations and operational irregularities within seconds.

So why wait? Call us today or get in touch with us by filling out the form below!

Imagine a supermarket where Peter is in charge of maintaining the quality and safety of perishable items. He must regularly check and record temperatures. But this is not the only task he has. Sometimes, he gets distracted by other pressing matters, and he forgets. This is a source of great frustration for him.

At times, Peter is so busy that he relies on other colleagues. But that also has its risks. Many times, he has experienced that his co-workers make his job even more challenging. Some misread thermometers, forget checks, or make horrible miscalculations. These mistakes lead to temperature fluctuations that can result in the loss of valuable inventory, leading to financial losses.

In the event of a cooler malfunction, Peter remains unaware of it until he conducts his next scheduled check. It can be embarrassing and frustrating for him when a customer is the one who discovers the problem first. This delay can result in a substantial loss of products.

Making energy and temperature reports is another headache for Peter. He must comply with the demands of the authorities, but sometimes there are inaccuracies that creep into his data. Human error is an ever-present risk. Peter tries to cope, but he wishes there was a smarter way of monitoring the coolers and freezers in the store.

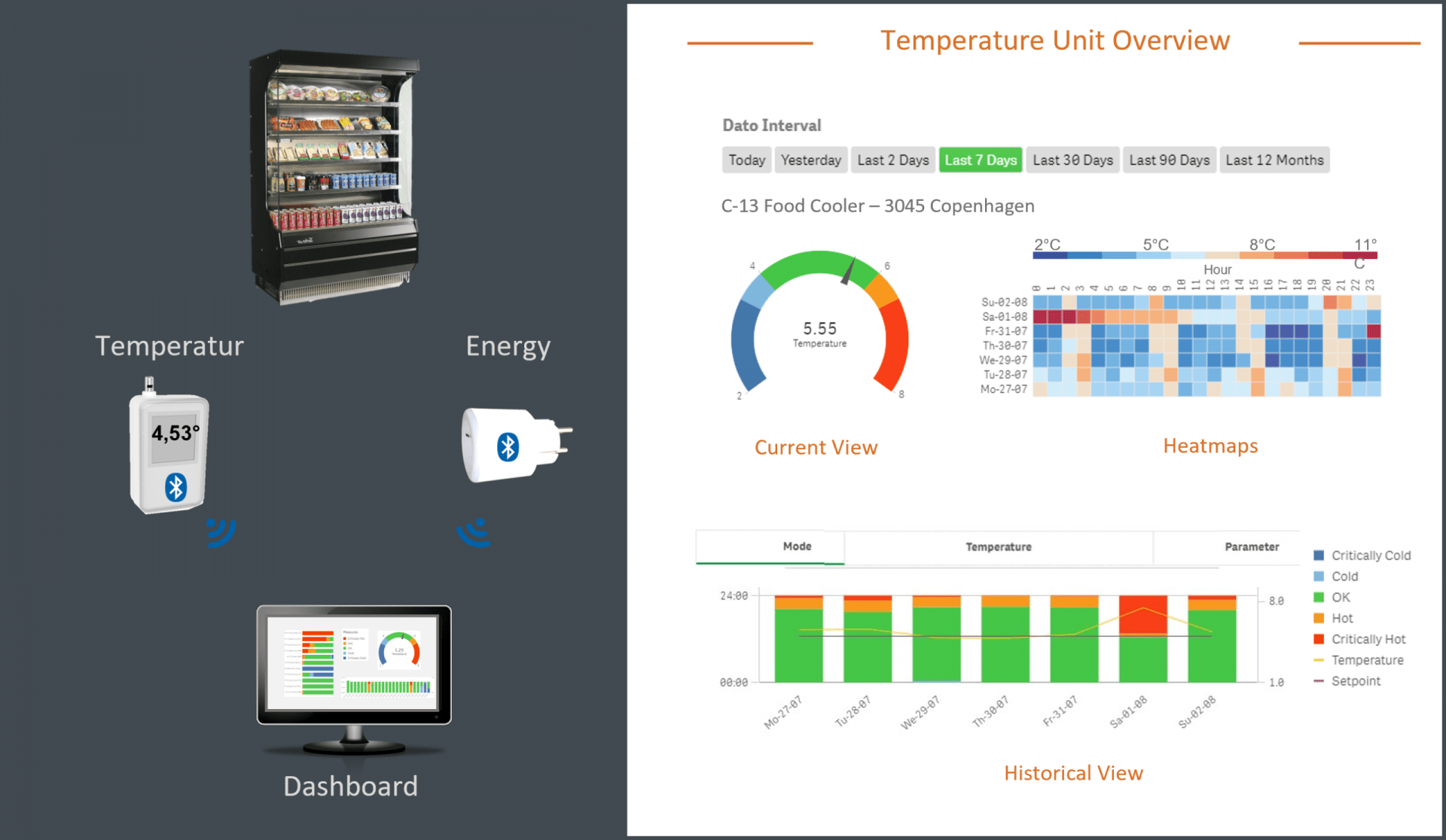

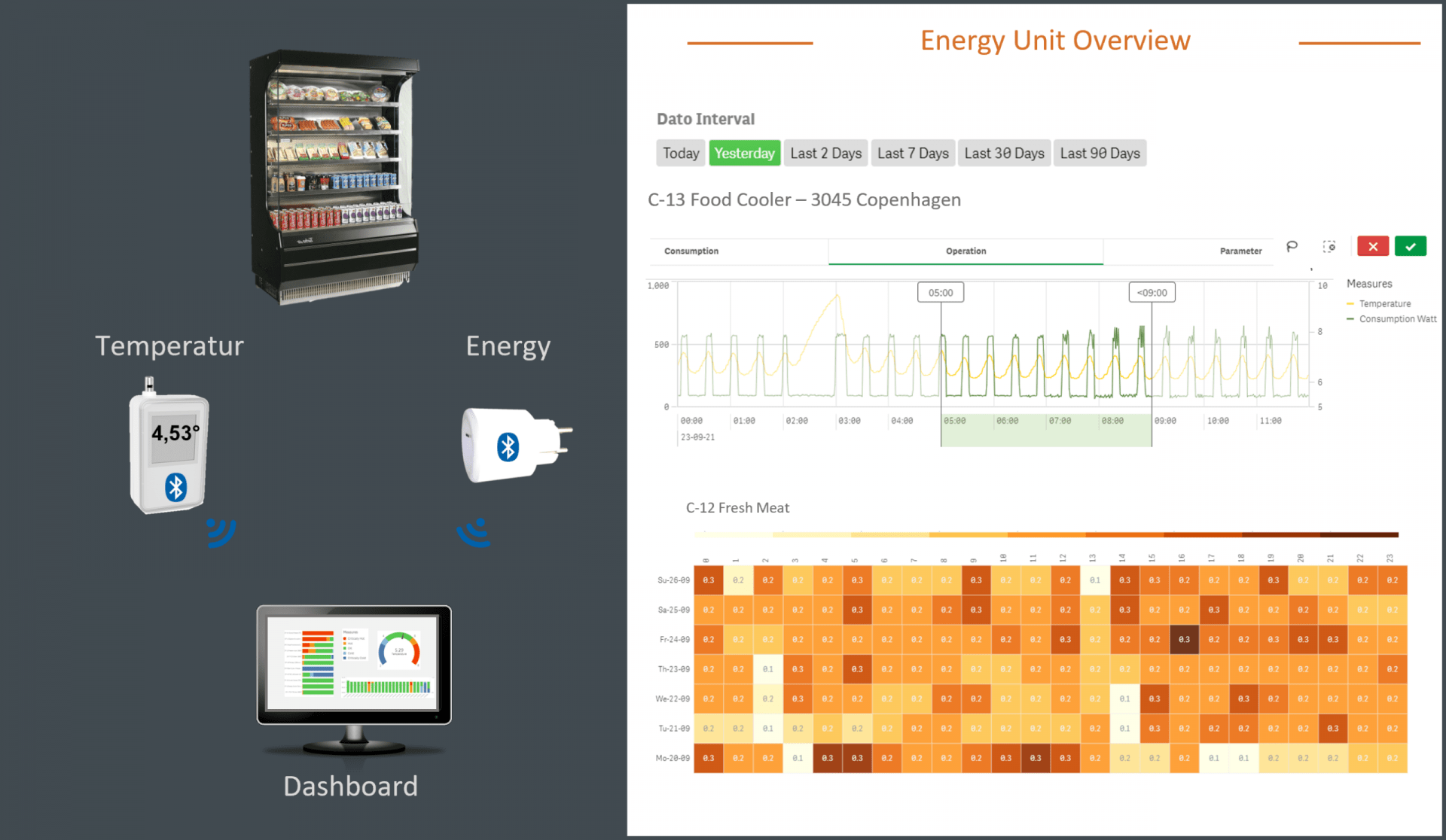

The frustrations associated with manual monitoring of freezers and coolers are a thing of the past for John. He has chosen our power and monitoring management system. He doesn’t have to conduct regular checks or record temperatures any longer. Electricity usage and temperature levels are automatically recorded. He can easily access this data on our cloud server.

John doesn’t have to rely on other colleagues to help him with his tasks. In the past, he would get frustrated when his co-workers would make mistakes. Today, John knows that our system takes care of all the monitoring and managing of the coolers and freezers in the store. He has no worries because there is no loss of valuable inventory either.

In the event of a freezer malfunction, John gets an instant notification right away. After installing our power and temperature management system, there are no longer any customers who complain about malfunctioning freezers.

Making energy and temperature reports has never been easier for John. His reports are highly accurate and consistently meet the authorities’ demands. Human error is not an issue anymore. John could not have been happier. The only thing he regrets is not having adopted our AI-driven system much earlier.

EMD Retail assists supermarkets and convenience stores in gaining full control of their displays, coolers, and freezers. We offer a reliable power and temperature management system.

Smart plugs and meters collect detailed data. Our system instantly identifies when cooling and freezing units are not operating optimally. Our clients receive instant notifications in case of anomalies. This immediate feedback enables staff to take corrective action swiftly, preventing the loss of perishable goods.

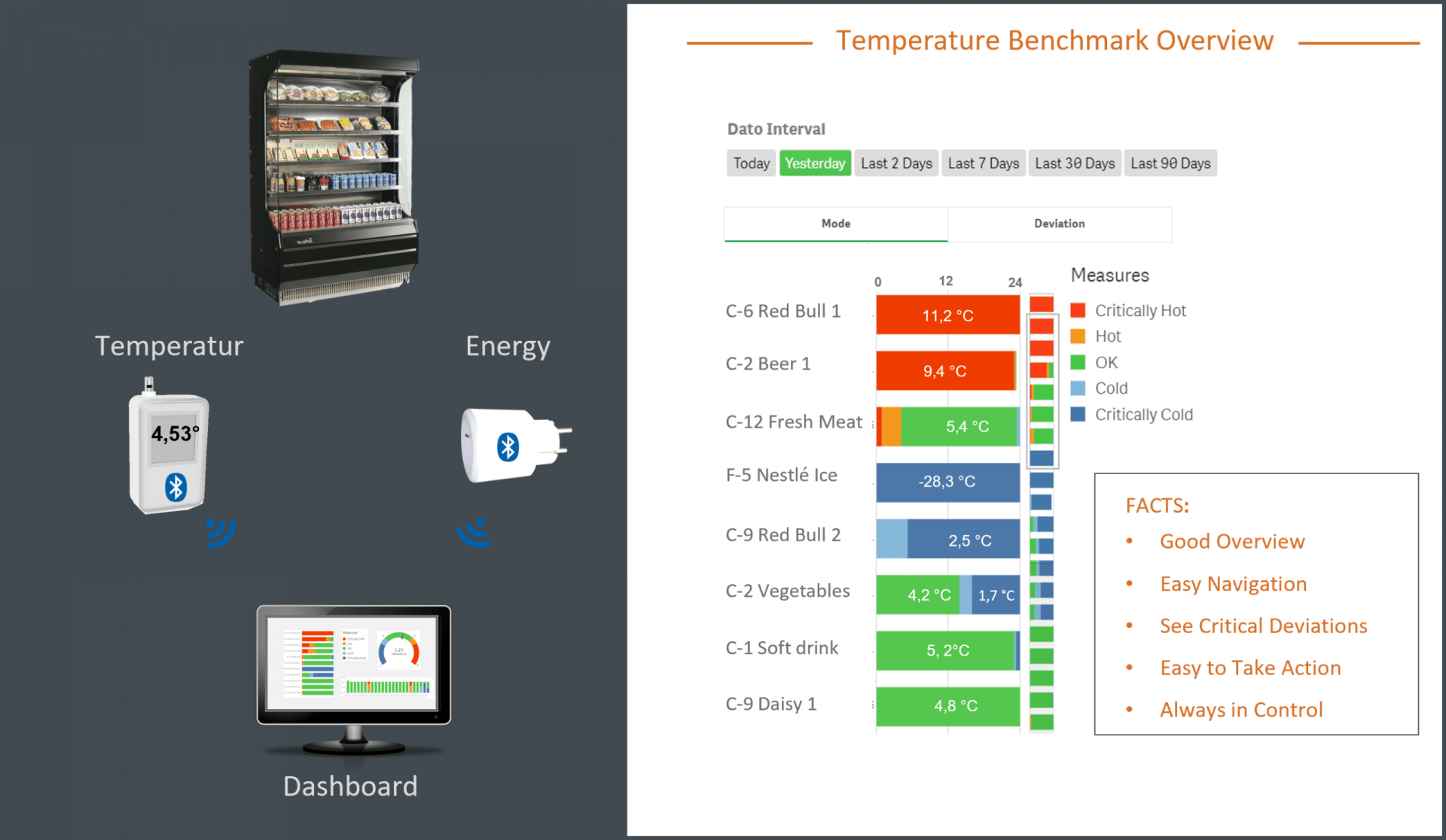

Our system also enables our clients to benchmark and compare energy consumption across different supermarkets. This gives them a competitive advantage, as their supermarket chain is consistently streamlined and error-free. Our clients also reduce labor costs associated with manual monitoring.

The system’s data logging creates comprehensive records that can be analyzed for trends and compliance purposes. This data helps our clients comply with food safety regulations and always keep a high product quality. This is an added value our clients appreciate and a solid reason to implement it in your stores. Give us a call or fill out the form above today.

Maintaining steady temperatures in commercial freezers and coolers safeguards the quality and safety of perishable items. Discover the numerous advantages of implementing AI-driven power and temperature management:

Our system empowers you with real-time monitoring and control capabilities. This precision eliminates temperature and power fluctuations, significantly reducing the risk of spoilage.

Your staff can effortlessly access up-to-the-minute power and temperature data on our cloud server. Our power and temperature management proactively issues alerts and notifications if temperatures or energy levels deviate from the desired range, enabling swift corrective measures to be taken.

You get a system designed to assist your supermarkets and convenience stores in complying with regulations, ensuring the safe storage of products and seamless audit processes.

Having only one employee keeping track of electricity usage and temperature levels reduces mistakes and results in more standardized control. This saves you money in terms of salary and energy waste.

Our power and temperature management system assists you in optimizing energy consumption in your commercial freezers and coolers. Our system also minimizes unnecessary cooling cycles. This contributes to extending the lifespan of your cooling equipment.

Our system gathers and archives historical temperature data. This data is a valuable resource for identifying trends, monitoring power and temperature fluctuations, as well as ensuring adherence to regulations and standards.

Investing in power and temperature management can result in substantial long-term cost savings. By preventing temperature and power fluctuations, supermarket chains can reduce product wastage, saving money on restocking. Additionally, the system's energy-efficient operation leads to lower utility expenses. The ability to promptly address issues minimizes the costs of equipment repair or replacement.

Our AI-driven system offers real-time power and temperature data, enhancing inventory management. Convenience stores can avoid overstocking or understocking issues, leading to cost savings and improved customer satisfaction. It also facilitates precise tracking of product shelf life, reducing the risk of selling expired or compromised goods.

Our system features self-monitoring, a critical aspect in maintaining the safety of perishable goods. Technical staff receive instant alerts of power and temperature deviations, allowing them to take corrective measures before product safety is compromised.

Power and temperature management can help your business become more competitive. Contact us today by filling out the form above.

When you choose EMD Retail’s solutions, we monitor the temperature of your systems and the energy consumption at your service stations. This prolongs the lifespan of your devices and equipment.

ROI ”A service station with 15 units, has an expected total ROI of 0.6-1.5 years.”